Purpose from the airlock system is to manage the move of staff, devices, and resources along with minimizing the transfer of contaminants or undesirable particles.

These airlocks provide a Actual physical barrier that forestalls cross-contamination and maintains the required cleanliness level.

These airlocks govern the motion of individuals getting into and leaving clear Areas. As we talked about above, several of those airlocks double as gowning rooms.

Then again, sink airlocks preserve reduced pressure inside the airlock, drawing air inward from adjacent Areas to trap particles. For example, in a very lab working with infectious illnesses, they may be beneficial in trapping contaminated air within so it doesn’t escape into other rooms.

Airlocks give a a lot more managed and protective atmosphere when compared to open up jar or cloth address fermentation, minimizing the chance of contamination.

Suitable airlock style, qualification, and Procedure are essential to circumvent cross-contamination involving regions with different cleanliness ranges. Airlocks really should give enough air modifications per hour and strain differentials involving places.

Enthusiastic about introducing cleanrooms with airlocks in your area? Reach more info out towards the professionals at Allied Cleanrooms and acquire a estimate on new here controlled environments currently.

Airlock doorways can typically be manually overridden in emergencies, but this should only be performed following proven protocols to make sure protection and preserve containment. Right training and strategies must be in place to deal with these overrides.

Content airlocks ought to be substantial enough to accommodate machines or item carts with no causing obstructions.

Regulators can even search for “The individual or described places or these types of other Manage systems with the business’s functions as are essential to reduce contamination or mix-ups in the program of…strategies.

HEPA (High-Performance Particulate Air) Filtration Systems are essential in airlocks making sure that the air coming into or circulating within the airlock is freed from contaminants, specifically particles as little as 0.

Typical routine maintenance and adherence to regulatory requirements ensure that airlocks proceed working properly, defending merchandise and staff from contamination challenges.

2. Airflow and Filtration: Airflow direction ought to be managed based on the cleanliness requirements of the adjoining rooms.

One-doorway airlocks will not offer the exact same amount of containment and separation as double-door systems, as they permit immediate publicity concerning two locations. Double-doorway airlocks are interlocked to ensure neither doorway could be opened simultaneously, Consequently furnishing top-quality contamination Regulate.

Tatyana Ali Then & Now!

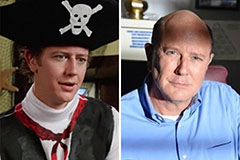

Tatyana Ali Then & Now! Judge Reinhold Then & Now!

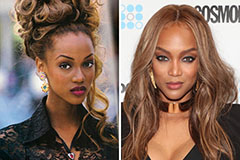

Judge Reinhold Then & Now! Tyra Banks Then & Now!

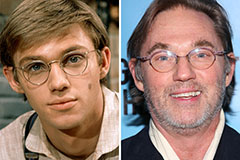

Tyra Banks Then & Now! Richard Thomas Then & Now!

Richard Thomas Then & Now! Dolly Parton Then & Now!

Dolly Parton Then & Now!